How to choose a correct MCB for your EV Charger?

How to choose a correct MCB for your EV Charger? Curve B or Curve C?

The appropriate type of Miniature Circuit Breaker (MCB) for an Electric Vehicle (EV) charger typically depends on the specific requirements and characteristics of the charger and the electrical installation. Here is a general guideline to help determine whether to use a Curve B or Curve C MCB:

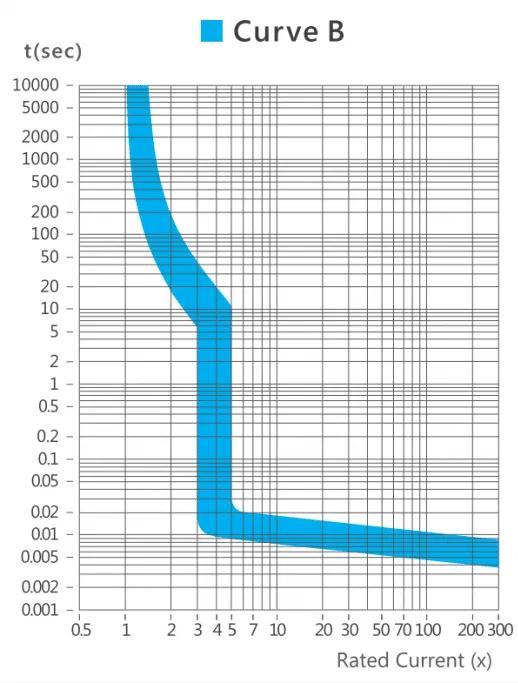

Curve B MCBs:

- Tripping Characteristics: Curve B MCBs trip when the current exceeds 3 to 5 times the rated current (In).

- Applications: These are typically used in domestic installations where the connected devices do not have high inrush currents. They are suitable for resistive loads with low inrush currents such as lighting and general-purpose circuits.

- Usage in EV Chargers: While Curve B MCBs could potentially be used for EV chargers, it is not always the best choice because EV chargers can sometimes have higher inrush currents, especially if they are of higher power ratings.

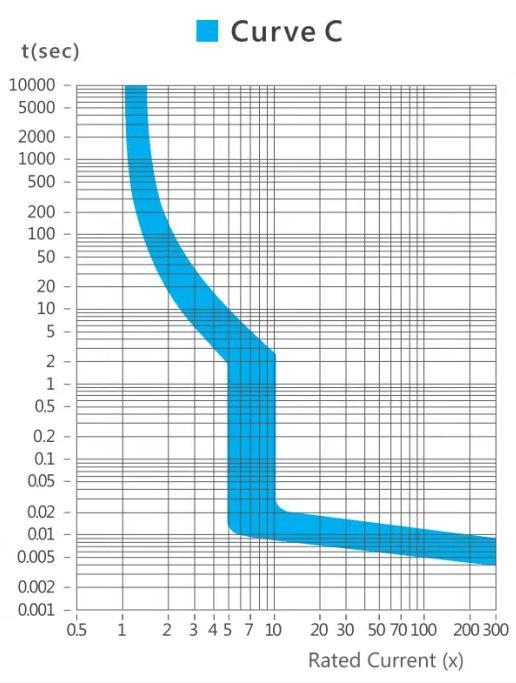

Curve C MCBs:

- Tripping Characteristics: Curve C MCBs trip when the current exceeds 5 to 10 times the rated current (In).

- Applications: These are commonly used for circuits with higher inrush currents such as inductive loads (motors, transformers) and certain types of electronic equipment.

- Usage in EV Chargers: Curve C MCBs are generally preferred for EV chargers because they can handle the higher inrush currents without tripping unnecessarily, providing more reliable operation.

Recommendation:

- Curve C MCB: Generally recommended for EV chargers to handle the potential inrush currents without nuisance tripping. This is especially important if the EV charger has a significant power rating and can create higher initial current spikes.

However, the final decision should be based on the specific charger model, its inrush current characteristics, the electrical installation, and any manufacturer recommendations. Consulting the installation manual of the EV charger and, if necessary, a professional electrician or engineer is advisable to ensure compliance with local regulations and safe operation.

What is the recommended cable size to be used for Single Phase 7.4kW and Three Phase 22kW?

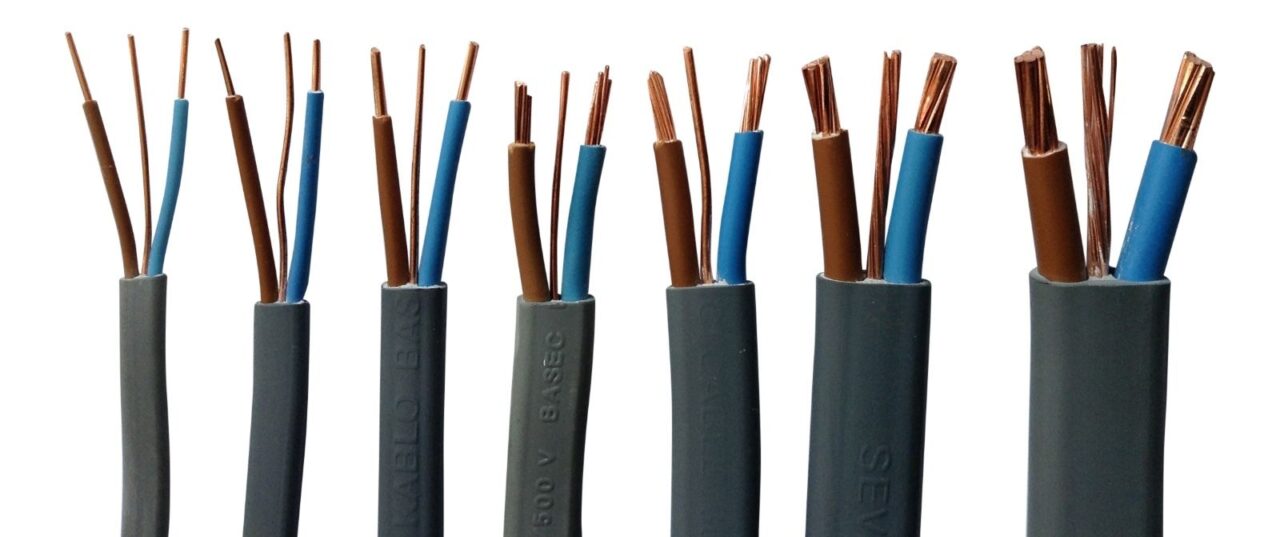

When selecting the appropriate cable size for an EV charger installation, it's important to consider factors such as the current load, the length of the cable run, and safety standards.

According to the Energy Commission Malaysia's "Guide on Electric Vehicle Charging System (EVCS)", the recommended cable sizes for Single Phase 7.4kW and Three Phase 22kW installations are as follows:

Single Phase 7.4kW EV Charger

For a single-phase 7.4kW charger:

- Power (P): 7.4 kW

- Voltage (V): 230V (common single-phase voltage)

Current Calculation:

Considering continuous load and safety margins, a current rating of around 32A is used.

Recommended Cable Size:

- Cable Size: For a current of 32A, a 6mm² copper cable is generally recommended. This size provides a good balance between safety, efficiency, and voltage drop over typical distances in residential installations.

- Cable Type: Use a high-quality, heat-resistant cable suitable for outdoor use if the installation is outdoors.

Three Phase 22kW EV Charger

For a three-phase 22kW charger:

- Power (P): 22 kW

- Voltage (V): 400V (common three-phase voltage)

Current Calculation:

Considering continuous load and safety margins, a current rating of around 32A per phase is used.

Recommended Cable Size:

- Cable Size: For a current of 32A per phase in a three-phase system, a 6mm² copper cable is sufficient to be used. However, Energy Commission recommends to use 10mm² copper cable.

- Cable Type: Use a high-quality, heat-resistant cable suitable for outdoor use if the installation is outdoors.

(GUIDE ON ELECTRIC VEHICLE CHARGING SYSTEM, Page no. 11)

Important Considerations:

- Cable Length and Voltage Drop:

- For longer cable runs, voltage drop needs to be considered. If the run is significantly long, it might be necessary to use a larger cable size to ensure minimal voltage drop and maintain efficiency.

- Installation Conditions:

- If the cable runs through areas with higher ambient temperatures, is buried underground, or runs through conduit with other cables, derating factors must be applied, which might require using a larger cable size.

- Local Regulations and Standards:

- Always ensure compliance with local electrical codes and standards, such as the Malaysian Standards (MS) for electrical installations or Energy Commission Malaysia - GUIDE ON ELECTRIC VEHICLE CHARGING SYSTEM (EVCS)

- Professional Consultation:

- It is highly recommended to consult with a licensed electrician or electrical engineer to ensure the correct cable size and type are used for your specific installation conditions.

- It is highly recommended to consult with a licensed electrician or electrical engineer to ensure the correct cable size and type are used for your specific installation conditions.

By adhering to these guidelines and considering the factors mentioned, you can ensure a safe and efficient installation of your EV charger.

What is the correct RCCB for an EV Charger Installation, Type A or Type AC?

For EV charger installations, the correct type of Residual Current Circuit Breaker (RCCB) is generally Type A. Here's why:

Type A RCCB:

- Detection Capability: Type A RCCBs can detect both AC residual currents and pulsating DC residual currents. This is crucial for EV chargers, as they can produce smooth DC residual currents and pulsating DC residual currents due to the electronic components used in the charging process.

- Safety: Type A RCCBs provide enhanced safety by detecting a wider range of residual currents that can occur during the charging process, ensuring better protection against electric shock.

Type AC RCCB:

- Detection Capability: Type AC RCCBs are designed to detect only AC residual currents. They are not suitable for detecting DC residual currents or pulsating DC residual currents.

- Limitations: Since EV chargers can produce DC residual currents, Type AC RCCBs may not provide adequate protection in such scenarios.

Summary:

For EV charger installations, Type A RCCBs are the recommended choice due to their ability to detect both AC and pulsating DC residual currents, ensuring comprehensive protection. Type AC RCCBs, being limited to detecting only AC residual currents, do not offer the necessary level of safety for EV charging systems.

Always consult with a qualified electrician to ensure compliance with local electrical codes and standards, and to verify the specific requirements of your EV charger installation.

What is the Installation Guide for AC EV Charger in Residential Areas?

Here is the comprehensive guide for you to installing a Type 2 AC EV charger in a residential area. Follow these steps to ensure a safe, compliant, and efficient installation based on Malaysian electrical standards.

Step-by-Step Guide:

1. Assessment and Planning

- Site Survey: Identify the best location for the charger considering convenience, proximity to your EV parking area, and accessibility to the electrical panel.

- Load Assessment: Assess your home's electrical load to ensure the system can handle the additional load of the EV charger. Consult with a licensed electrician if necessary.

2. Choosing the Charger

- Charger Type: Select a Level 2 (240V) charger with a Type 2 connector for faster charging.

- Compatibility: Ensure the charger is compatible with your EV and adheres to Malaysian standards.

3. Electrical Upgrades (if needed)

- Panel Upgrade: Upgrade your electrical panel if it cannot support the additional load.

- Dedicated Circuit: Install a dedicated circuit for the EV charger to prevent overloading other circuits.

4. Permits and Regulations

- Obtain Permits: Apply for necessary electrical permits from local authorities.

- Compliance: Ensure compliance with local electrical codes and standards, such as the Malaysian Standards (MS) for electrical installations.

5. Installation

- Mounting the Charger: Securely mount the charging unit on a wall or pedestal. Ensure it is weather-protected if installed outdoors.

- Wiring: Run conduit and wiring from the electrical panel to the charger location using appropriately rated wires.

- Component Selection: Depending on whether you have a single-phase or three-phase electrical supply, select the appropriate components:

- Single Phase Supply:

- MCB (Miniature Circuit Breaker): Use an appropriate MCB to protect the circuit from overcurrent. Curve C MCBs are recommended.

- RCCB (Residual Current Circuit Breaker): Install an RCCB for additional protection against electrical shocks.

- SPD (Surge Protection Device): Install an SPD to protect against voltage spikes.

- Isolator: Include an isolator switch to safely disconnect the charger for maintenance.

- Three Phase Supply:

- MCB: Use a three-phase MCB to handle higher current loads.

- RCCB: Install a three-phase RCCB.

- SPD: Ensure a three-phase SPD is in place.

- Isolator: A three-phase isolator switch should be installed.

- Single Phase Supply:

6. Testing and Commissioning

- Electrical Tests: Conduct tests to ensure proper wiring, grounding, and connection. Verify voltage, current, and continuity.

- Charger Test: Connect your EV and initiate a charging session to ensure proper operation.

7. Inspection

- Schedule Inspection: Arrange for an inspection by local authorities to verify that the installation meets all safety and code requirements.

- Obtain Approval: Get final approval from the inspector to certify the installation.

8. Final Setup

- User Configuration: Set up user-specific settings on the charger, such as charging schedules or power limits.

- Documentation: Keep all relevant documentation, including permits, inspection reports, and user manuals, for future reference.

Important Components for AC EV Charger Installation:

- EV Charger Unit: The main device for charging your EV.

- MCB (Miniature Circuit Breaker): Protects the circuit from overcurrent and short circuits. Use Curve C MCBs for EV chargers.

- RCCB (Residual Current Circuit Breaker): Provides protection against electrical shocks by detecting leakage currents.

- SPD (Surge Protection Device): Protects against voltage spikes and surges.

- Isolator: A switch to safely disconnect the charger from the electrical supply for maintenance or emergencies.

- Dedicated Circuit: A separate circuit designed to handle the load of the EV charger.

- Wiring and Conduit: Properly rated electrical wires and conduits to ensure safe transmission of electricity.

- Mounting Hardware: Brackets and hardware needed to securely mount the charger.

- Permits and Documentation: Necessary paperwork to comply with local regulations.

Additional Tips:

- Future Proofing: Consider future needs, such as upgrading to a higher power charger or adding more chargers.

- Smart Chargers: Opt for chargers with smart features like Wi-Fi connectivity for monitoring and scheduling.

- Professional Assistance: Hiring a licensed electrician ensures the installation meets all safety standards and regulations.

By following these steps and ensuring the inclusion of necessary components, you can ensure a safe, efficient, and compliant installation of your Type 2 AC EV charger in your residential area in Malaysia.

Call us to schedule a consultation today!

Sep 10,2024